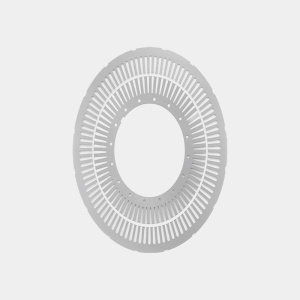

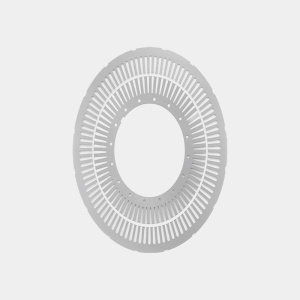

Y2 series motor rotor laminations suppliers

Y2 Series Motor Rotor Laminations Suppliers Overview The Y2 series motor is a widely used three-phase asynchronous motor known for its efficiency, reliability, and cost-effectiveness. A critical component of these motors is the rotor lamination stack, which plays a vital role in reducing energy losses, improving magnetic flux distribution, and ensuring smooth operation. Suppliers of Y2 series motor rotor laminations must adhere to strict material, design, and manufacturing standards to meet industry requirements. Material Selection High-quality rotor laminations for Y2 motors are typically made from silicon steel (electrical steel) due to its excellent magnetic properties and low core loss. The material grade, thickness (usually between 0.35mm and 0.5mm), and insulation coating (such as C5 or C6) are carefully selected to minimize eddy current losses and enhance motor efficiency. Suppliers must ensure consistent material quality to avoid performance variations. Precision Manufacturing Processes The production of rotor laminations involves precision stamping or laser cutting to achieve tight tolerances and smooth edges. Advanced tooling and die designs are essential to maintain dimensional accuracy, especially for the slots and keyways that accommodate rotor bars. Some suppliers also offer custom designs to meet specific motor performance criteria. Quality Control and Testing Reputable suppliers implement rigorous quality control measures, including dimensional inspections, material testing, and stacking factor verification. Eddy current testing and visual inspections ensure defect-free laminations. Proper stacking and alignment are crucial to prevent motor vibration and noise. Customization and Flexibility Suppliers often provide tailored solutions based on customer requirements, such as different slot configurations, stacking heights, or insulation treatments. Custom coatings or heat treatments may also be applied to enhance durability and performance. Global Supply Chain and Compliance Leading suppliers operate within a global supply chain, ensuring timely delivery and competitive pricing. Compliance with international standards (e.g., IEC, NEMA) is essential for manufacturers serving diverse markets. Conclusion Suppliers of Y2 series motor rotor laminations must combine advanced manufacturing techniques, strict quality control, and material expertise to deliver high-performance components. Their role is critical in ensuring the efficiency and longevity of Y2 motors across industrial, commercial, and automotive applications.

제품

범주:

-

실리콘 스틸 라미네이션

분류: 펀칭 및 벌크 필름조회수: 139번호:릴리스 시간: 2025-09-30 15:12:27실리콘강 적층: 특성, 응용 및 제조 공정전기강판 또는 변압기강판으로도 알려진 실리콘강판 적층은 전기전자 산업에서 널리 사용되는 특수 소재입니다. 독특한 특성으로 인해 변압기, 전기 모터 및 발전기와 같이 효율적인 에너지 변환이 필요한 응용 분야에 없어서는 안 될 요소입니다. 이 기사에서는 규소강 적층의 특성, 제조 공정 및 주요 응용 분야를 살펴보고 현대 기술에서의 중요성을 강조합니다.1. 실리콘강 적층 소개실리콘강 적층은 실리콘(일반적으로 1%~6.5%)을 함유한 강철 합금의 한 유형입니다. 실리콘을 첨가하면 재료의 전기 저항력이 크게 향상되고 와전류 및 히스테리시스로 인한 에너지 손실이 줄어듭니다. 이러한 특성으...

뉴스

범주:

검색 결과가 없습니다!

케이스

범주:

검색 결과가 없습니다!

비디오

범주:

검색 결과가 없습니다!

다운로드

범주:

검색 결과가 없습니다!

모집

범주:

검색 결과가 없습니다!

추천 제품

검색 결과가 없습니다!

모바일: +86 13738592999

모바일: +86 13738592999 전화: +86(576) 89307999

전화: +86(576) 89307999 이메일: sales@zjxinzheng.com

이메일: sales@zjxinzheng.com 주소: 삼문 해안공업도시

주소: 삼문 해안공업도시

왓츠앱

왓츠앱 핸드폰

핸드폰